When you first start your ecommerce business, your order volume is low enough to handle your own fulfillment, so a 3PL is likely the last thing on your mind.

But as you grow, you may get so many orders that all your time is spent fulfilling customer orders. If you get overwhelmed with fulfillment, your day-to-day business operations may fall behind, leading to decreased customer satisfaction.

To keep things running smoothly, it’s ideal to pass off your order fulfillment to a third-party logistics (3PL) company. They’ll handle order fulfillment while you focus on the aspects of your business you know best. When you choose a fulfillment provider, you’re choosing a business partner, so it’s not a decision to take lightly.

3PL Logistics Defined

A third-party logistics provider handles logistics operations for other businesses. Many fulfill multiple roles, which you can pick from to suit your business needs. The three parties involved are:

- The business

- The logistics provider

- The shipping carrier

As your business scales, you can expand with inventory management, kitting, and assembly. (If you have a subscription box business, for instance, you may need a service that offers kitting.)

Here is a list of leading third-party logistics companies:

- Ryder

- FedEx

- UPS

- XPO Logistics

- C.H. Robinson

- DHL

- Schneider National

- TLC

- Penske

- APL Logistics

- Danzas AEI

- Hub Group

You are probably familiar with many of these, like UPS and FedEx, but may not recognize others. This is because they handle different sectors of logistics. Some may only serve certain regions, others may handle top-level B2B needs, while the more familiar ones deliver packages to your doorstep. They are all part of a global supply chain.

Understanding Shipping and Logistics

Shipping is part of logistics. Shipping logistics can become quite complex. It involves:

- Keeping an eye on the entire supply chain, planning the warehousing, storage, and handling of items while monitoring inventory levels.

- Unitization and packaging

- Inventory control

- Transportation and shipping, including less-than-truckload (LTL) freight shipping (shipments over 150 pounds).

- Information and control

Types of 3PL Providers

Most 3PLs offer various services, but not all of them offer the same combinations. Some are more specialized than others – but most will focus on one of the following functional areas, which are often aligned with their core competencies.

By Service

3PLs can be categorized by service type, which can usually be broken down into three further subcategories: simple service, combined service, and value-added services.

Simple service is the most basic level, offering a single aspect of logistics or a single leg of the supply chain. For example, using USPS to deliver your products to customers.

Combined service offers two or more aspects of logistics or multiple supply chain segments. For example, Amazon fulfillment centers that warehouse and deliver your products.

Lastly, value-added services go beyond pure logistics to offer additional assistance. Common examples include product assembly, kitting, or product personalization in addition to logistics services.

Specific examples of services include:

- Warehousing

- Trucking

- Ocean Carriers

- Air Freight

- Freight brokerage

- Industry

- Logistics Management

- Value-Added Services

- Logistics Consulting

Simple service providers generally offer only one of these services. Combined services offer multiple. Value-added services offer one or more in addition to services that do not fall under the traditional logistics umbrella and are not included in this list.

By Operations (or Industry)

Most 3PLs can also often be categorized by the type of operations or industries they service. For example, the needs of medical logistics can vary in significant ways compared to logistics for an automotive business. Here are six common 3PL categorizations by industry:

- Consumer

- Retail

- Computer

- Automotive

- Medical

- Chemical

If you are looking for a 3PL, you can narrow down your options by selecting those that focus on your type of business.

By Contract Type

Every 3PL company can also be grouped by their contract type. You have common, contract, and exempt carriers among public carriers.

Common carriers are open to the public and transport freight for anyone. An example is walking into a FedEx to pay to have a package shipped.

Contract carriers serve only a limited number of clients by contract rather than being open to the public. An example would be a transportation business that exclusively transports medical supplies for a group of related hospitals.

Exempt carriers are unique cases where the goods being transported are exempt from one form of regulation or another. They may only be permitted to transport certain types of freight to qualify for exemption. An example would be livestock.

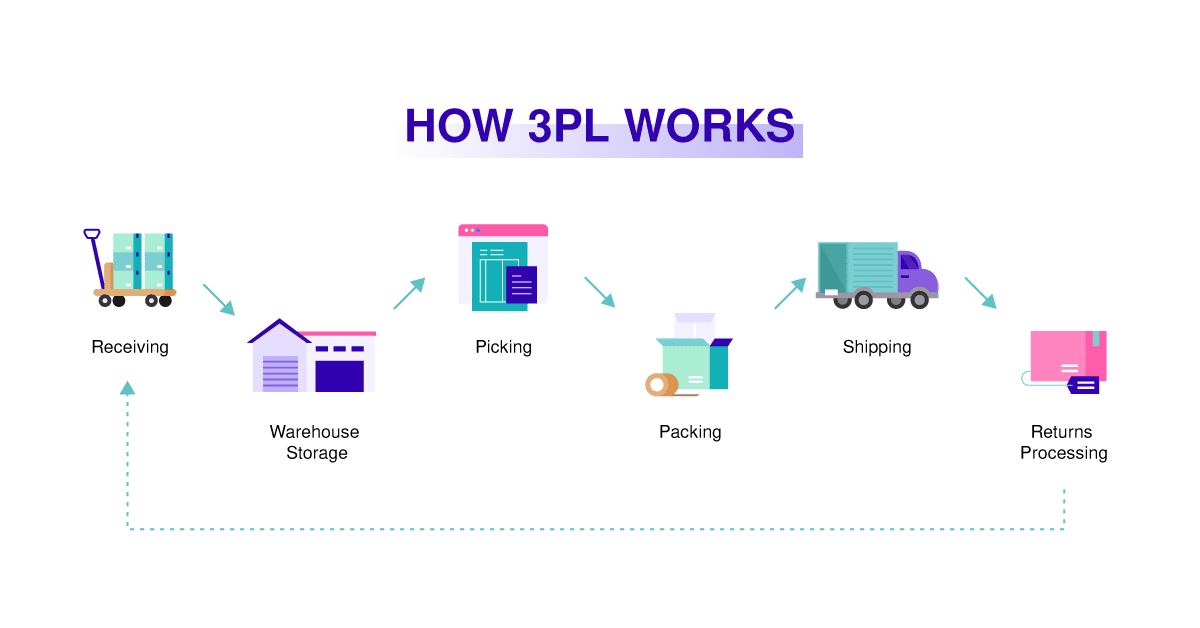

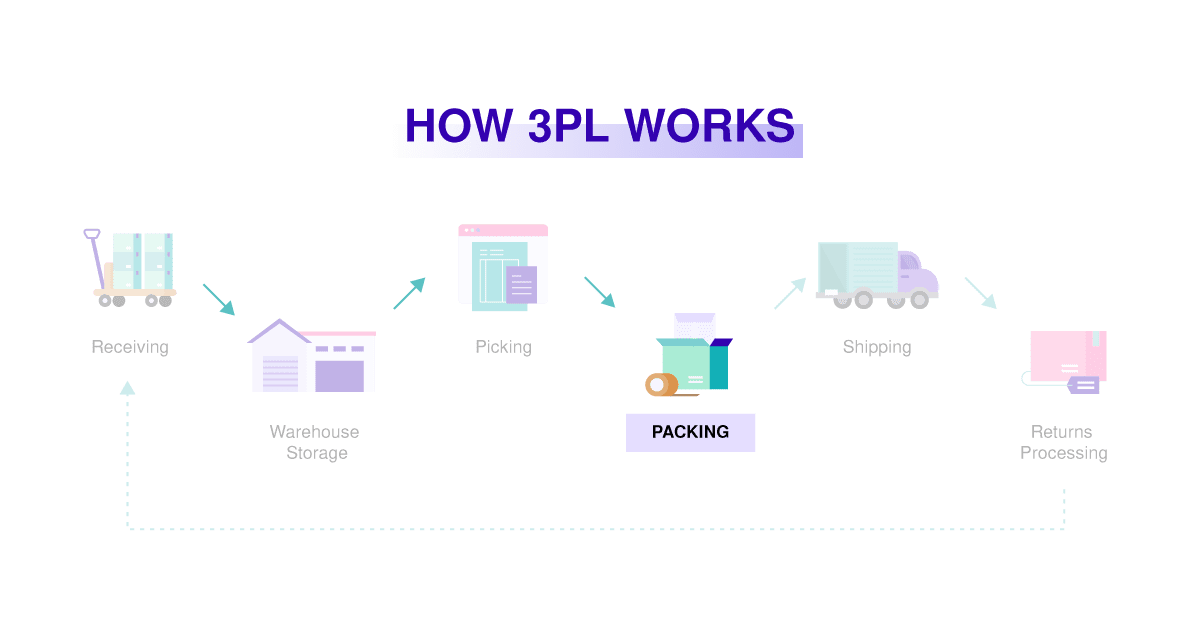

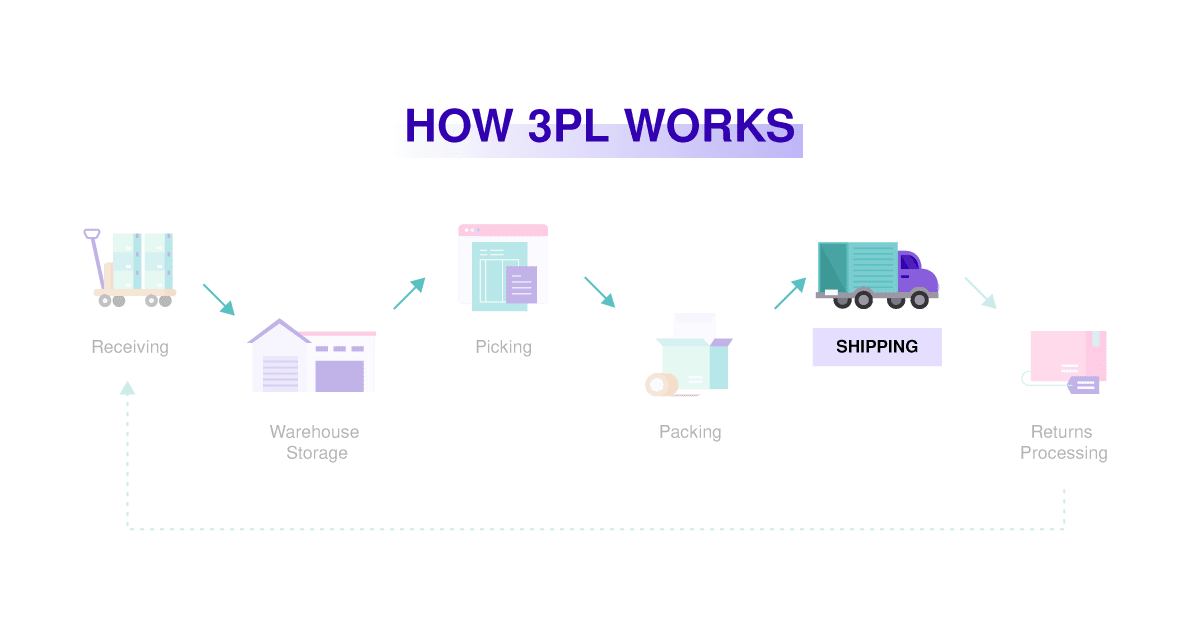

How 3PL Works

While 3PL services will vary from one to another, having a well-rounded understanding of what these companies tend to offer will help you better predict their value and what to look for. You don’t need to be a 3PL fulfillment expert, but it helps to understand how the pieces fit together when comparing your options for logistics services.

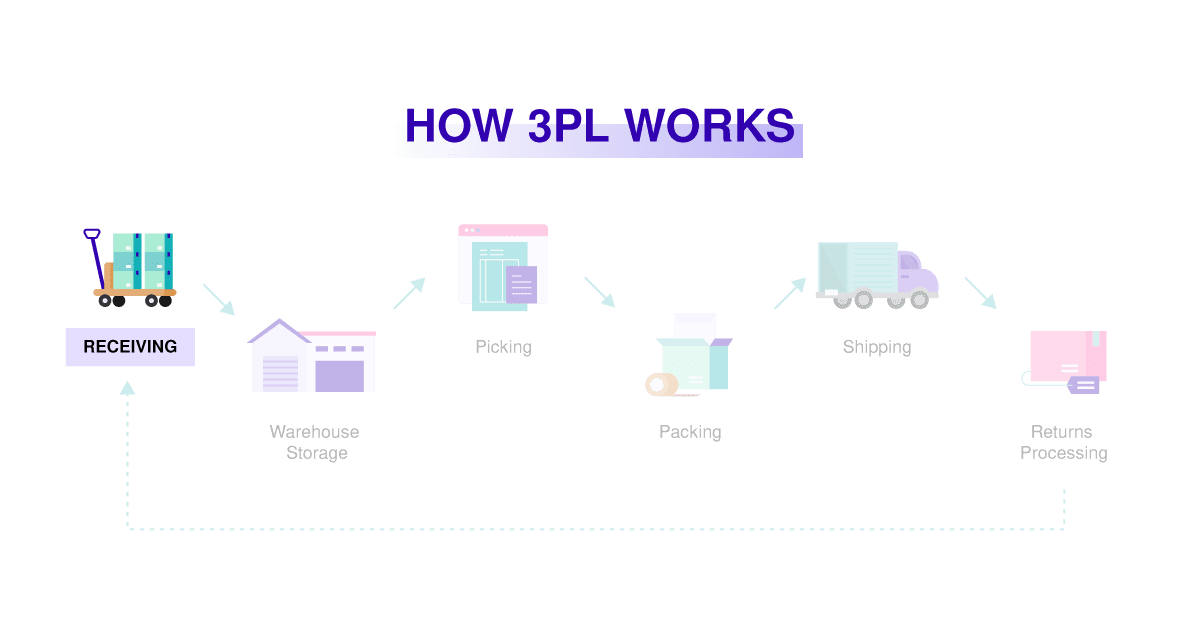

Receiving

Before they can ship orders for you, the 3PL must receive your inventory. “Inbound receiving” is the process of accepting your inventory into the warehouse and storing it until a customer places an order. This also includes tracking inventory by adding it to the provider’s ERP software so they have an accurate stock count in their system.

Some 3PL companies require you to manually upload orders into their system. This may mean using spreadsheets that include order details, customer details, and shipping details. This method is manageable if you don’t have a lot of orders, but quickly becomes inefficient and prone to errors as order volume grows.

Every 3PL has its own storage capacity and process for how inventory is received and stored. When you choose a partner, make sure you understand their process.

ShipBob, for example, requires clients to fill out a Warehouse Receiving Order (WRO). This ensures they know exactly what products they’re receiving and how many units of each, to keep things organized.

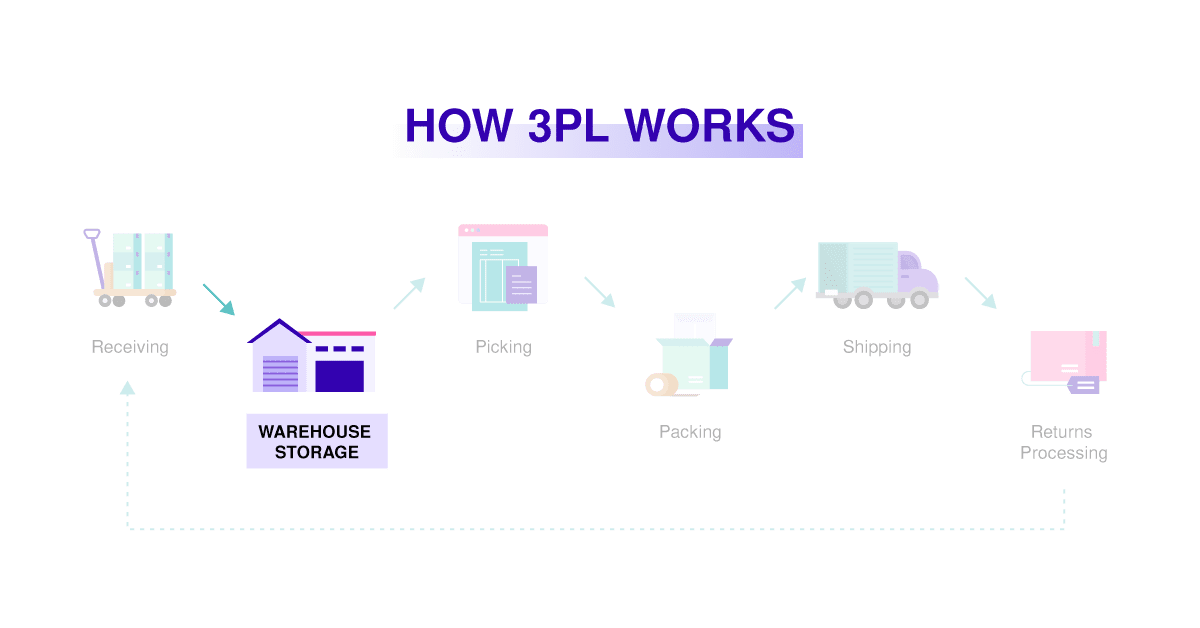

3PL Warehouse Storage

After receiving inventory, it moves to storage, which may or may not be distributed across multiple fulfillment centers to allow for faster shipping and delivery. Warehousing, including a warehouse management system, may sound simple, but often requires careful planning and serious labor to stock and organize a variety of products and maintain optimal inventory levels. It may involve forklifts, high elevations, and a large amount of real estate.

With ShipBob, each SKU will have a dedicated storage location that may be on a pallet, on a shelf, or in a bin.

Since different operations will have their own storage capacity and warehouse space is not a one-size-fits-all industry, it’s crucial to work with a facility that has more than adequate storage space for your current inventory. As your business grows, in terms of product line and order volume, your 3PL must be able to scale with you.

A 3PL is not on-demand warehousing. That’s just a storage facility that meets your needs with extra space in miscellaneous warehouses.

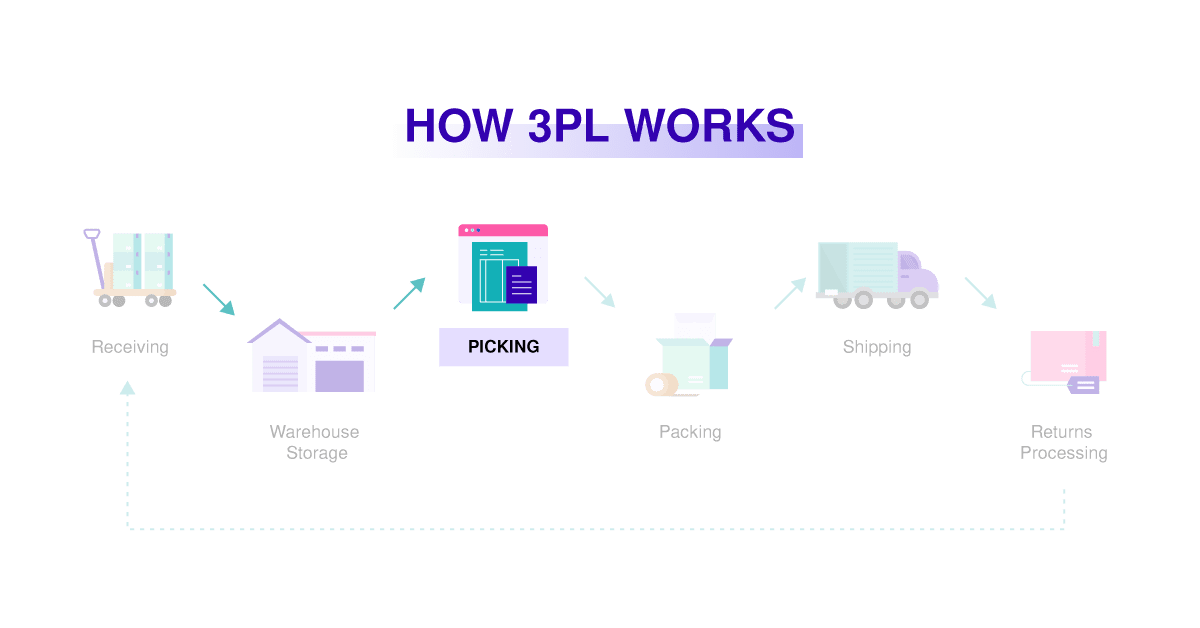

Picking

After your customer hits “submit” on the order, the 3PL fulfillment process starts. Picking is the process of locating and acquiring your product(s) from the warehouse. Again, this can require mechanized labor or be as simple as pulling a small item off of a shelf by hand. Many orders include more than one product, meaning the 3PL warehouses have to “pick” multiple items to fill each order.

The ideal 3PL partner uses real-time technology that integrates with your ecommerce platform or online marketplace. Order information is automatically sent as orders are placed. This streamlined approach makes it easier to automate shipping by tracking orders, shipments, and inventory stock levels remotely using a warehouse management system in real-time.

Once your 3PL receives the order, it will be sent over to the warehouse picking team, where a picker receives the list of items, quantities, and storage locations. The picker will collect the ordered products from their locations, and then it moves to the next phase.

Packing

Items pulled straight off of the shelf or pallet usually aren’t ready to slap a label on and put in the mail. After picking the items, the 3PL has to package them sensibly. This is generally a balancing act between providing good customer service in the form of safe and cost-effective shipping and presentation upon arrival.

Oftentimes a 3PL provider will allow you to supply or decide on different packaging options so your products arrive to customers how you want them to. The packing materials used to pack and ship your orders will vary depending on your 3PL’s capabilities, the items being shipped, and your brand preferences.

Common standard packaging materials include:

- Plain, unbranded boxes

- Bubble mailers

- Poly bags

- Dunnage and filler

- Packing tape

Depending on the logistics company you use, you may be charged for packing materials separately, while others include it as part of their fulfillment services.

Some 3PLs allow you to ship products to customers in your own branded packaging (see Packlane). If having a branded unboxing experience is important to you, opt for a provider that allows for custom packaging and inserts.

Shipping

After the items are packed, it’s time to ship. The majority of 3PLs will buy and print shipping labels for you to help you save on the cost of shipping . While some companies have preferred shipping partners, others utilize shipping software to compare prices from multiple carriers to provide the most affordable shipping option for shippers. Since 3PL freight companies tend to do a lot of less-than-truckload shipping, they often receive discounted rates and can pass those savings on to you.

Carriers such as UPS, USPS, FedEx, and DHL pick up orders from warehouses to ship to the customer, ensuring efficient shipping rates for shippers. The carrier and shipping speed will vary from one order to the next, based on the available shipping options, what the customer paid for, 3PL partnerships and policies, etc.

After the order ships, if you use a 3PL with integrated technology options, the tracking details will automatically be pushed back to your system and sent out to the customer.

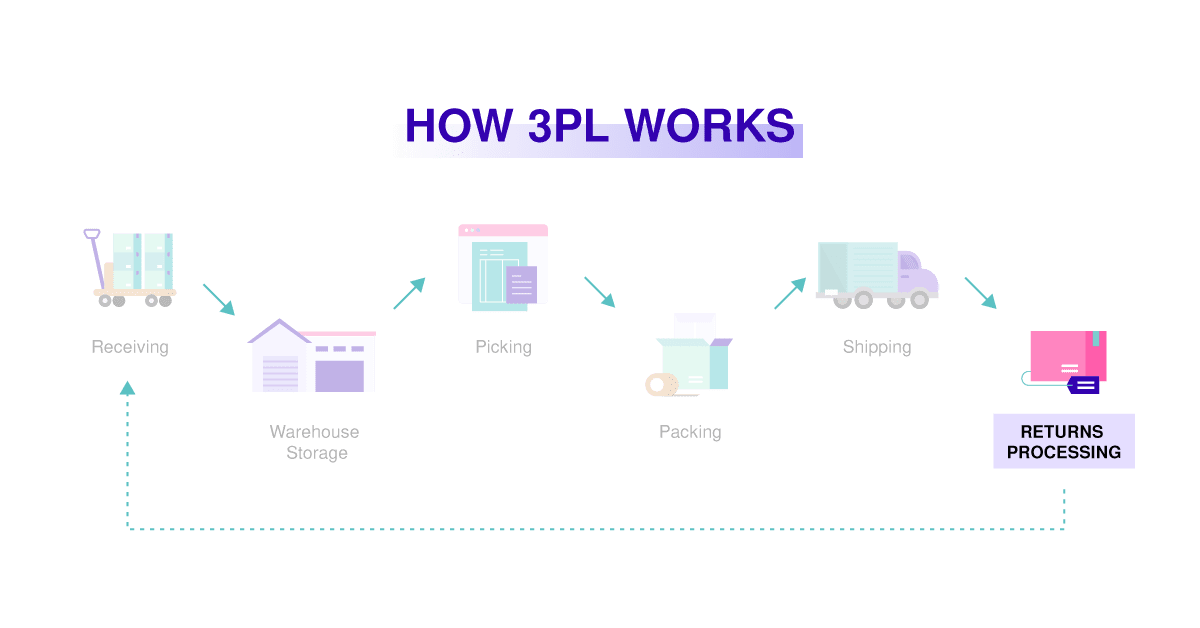

Returns Processing

Some 3PL companies also offer returns processing, otherwise known as reverse logistics. If a customer returns an order (it’s the wrong product, doesn’t fit as expected, etc.) it goes back to your 3PL. Once received, the 3PL will process the return and either dispose of or restock the item according to your preferences and policies.

You’ll also have the option to have the 3PL provide return shipping labels on your behalf, which is convenient for you and your customers. You don’t have to handle returns in-house, and customers can easily track their return order status from various customer support channels with a well-integrated 3PL system.

How 3PL Works

In summary, here is the general process for how logistics processes in 3PL work for most retailers. While different 3PL businesses may operate slightly differently, the fundamental logistics processes of a 3PL are pretty universal.

The first step is partnering with a 3PL vendor and supplying them with your products for their warehouse. This can include a number of processes and system integrations to track and manage your inventory.

When customers order inventory from your website or other ecommerce platform, the order and customer information are sent directly to the 3PL fulfillment company, which helps streamline sales channels. Warehouse workers then pick, pack, and ship your orders from the 3PL warehousing directly to the customer. In other words, they “fulfill” the order on your behalf.

In some cases, 3PL warehouses can be directly involved in supply chain operations, meaning you can have the products you source sent directly to them. This essentially removes you from any actual product handling. Different 3PLs have different levels of supply chain involvement, so give some thought to your process before shopping for 3PLs.

When to Use a 3PL

While using a 3PL certainly sounded convenient for a number of reasons, the fact is that for many ecommerce merchants, it is more of a necessity. Particularly for startups and other growing enterprises, ensuring customer satisfaction and keeping up with all of the moving pieces of the fulfillment puzzle can be a real challenge.

More importantly, if your current processes are insufficient for your operation, they can stifle growth in a number of ways. If you are encountering any of the following scenarios, partnering with a good 3PL logistics company should be a serious consideration.

1. Your ecommerce fulfillment processes are holding you back

Especially for startups and small-sized companies experiencing rapid growth, a 3PL can be invaluable for keeping up with ever-increasing order volumes. It can be hard enough to design a process to meet your current needs, but repeatedly expanding warehouse space, shipping volume, and packing teams requires a lot of time and resources.

Partnering with a 3PL warehouse company that can keep pace with your growth can remove a lot of obstacles and accelerate your success.

2. Your team is too small, overworked, or inexperienced

Managing a team to handle logistics and operate a warehouse is a feat of organization and planning. Especially as businesses grow and order volumes increase, your existing team may be stretched too thin to keep up.

Rather than trying to hire and train new employees, letting a 3PL partner take that burden off of your hands is often a much easier and more effective move. This not only saves you a lot of cost-effective headaches but frees up resources and team members to focus on other important tasks.

3. Errors are happening in inventory management and picking

Whether it’s because your team is stretched too thin, your warehouse isn’t well organized, or simple miscommunication, errors can be very costly in ecommerce. Not only can you lose valuable inventory or have to pay return shipping costs, but you are also creating bad customer experiences.

3PLs can devote much more attention to these matters, reducing errors and increasing efficiency.

4. You’re unfamiliar with a new market region

Whether you’re opening a new branch, moving locations, or just looking to expand your reach, getting your foot in the door isn’t always easy. For example, if you are trying to break into an international market, the shipping rules and processes may differ in another country.

Partnering with 3PL fulfillment services in a region offers a shortcut to a pre-established logistics network to save you time and hassle.

5. It is too risky to invest in logistics infrastructure

It is easy to imagine the 3PL definition hypothetically and not fully appreciate the magnitude of logistics infrastructure. Massive warehouses, entire heavy equipment and labor departments, specialized software, and more go into an efficient fulfillment operation. For many prospective business ventures, the financial investment alone is a non-starter.

3PL partners already have the infrastructure, allowing you to acquire everything you need with minimal risk and investment.

3PL vs. 4PL

In researching 3PLs, you may also find the term 4PL, or fourth-party logistics. The difference here is that you add another party to the mix. It adds another degree of separation between you as the ecommerce merchant and the EDI asset carrier shipping your products.

If you contract a 4PL, they will manage the 3PL tasks for you as their client. You may also hear this called “double brokering.”

Fourth-party logistics typically provide end-to-end supply chain management for their clients, going beyond 3PL to offer inventory procurement, manufacturing, etc.

Benefits of 3PL

No matter what your company sells and the services your 3PL offers, the partnership has plenty of benefits. Though 3PLs all vary in capability, all of them will help with inventory management, packing and shipping, and your overall supply chain, which helps to increase productivity and maximize profitability.

Saves Your Business Time and Money

When you partner with a 3PL, you immediately reap cost savings since you don’t have to buy your own warehouse or rent warehouse space. The more your business grows, the more you’ll spend on in-house fulfillment. You’ll pay not only for the storage space, but for the forklifts and other heavy equipment, labor, warehouse management software, labor costs, etc. Those extra costs add up quickly.

For many small businesses, it makes sense to save those costs and the time you’d spend filling orders yourself by outsourcing your fulfillment to a 3PL. You can focus the time you’d spend filling boxes, printing shipping labels, and scheduling pickups to more strategic initiatives, like new product development and marketing campaigns. Many 3PL service providers operate with a network of sales channels and fulfillment centers, making it possible to spread your inventory around the country, so you can save money on shipping.

Pass Shipping and Logistics to Experts

Being an expert in your industry doesn’t mean you have the time to become an expert in logistics, too. When you work with an experienced third-party logistics company, you’ll be able to use their experience and technical resources to keep all parts of your business running smoothly. You’ll have full supply chain visibility, and you won’t have to take time away from other value-added activities to focus on order fulfillment.

Reach More Customers

Handling things on your own may limit your exposure to a single region. If you want to go nationwide or even internationally, partnering with a 3PL helps keep costs down since they have access to a network of carriers and distribution centers that you, as a small business owner, would struggle to achieve on your own.

Most 3PL companies have expanded networks with fulfillment centers throughout the country (and many across the globe as well), making it easier for you to get packages anywhere you need them to go, faster and more affordably.

3PL Costs

What you’ll pay for 3PL services depends on the company’s pricing model, as well as what your business needs. Some costs to keep in mind as you choose your fulfillment company include:

- Onboarding Costs: Costs associated with bringing your business into the warehouse and getting your technology up and running

- Inventory Receiving Costs: Costs associated with accepting and storing your inventory. One type of 3PL may charge per unit, while other 3PLs may charge per pallet, per hour, or a flat rate.

- Inventory Storage Costs: Warehousing fees associated with inventory that sits in storage every month. These may be charged by per SKU, per unit, or fixed fees based on the warehouse space you take up.

- Pick and Pack Costs/Fulfillment Service Fees: Costs associated with picking and packing the orders; some companies include this in their costs. Some don’t charge at all for orders under a certain threshold. Others will charge a per-item fee based on order size.

- Packaging Costs: Some companies may charge for packaging materials like boxes and airfill as separate line item.

- Kitting Costs: Kitting, sometimes also referred to as assembly, references any specific ways items are packed or arranged before they’re shipped to customers. Because the service is unique for each client, fees vary depending on the complexity of the packing. Fees are usually based on the number of items to be packed, and how many units need to be assembled.

- Shipping Costs: This is the amount the company charges to get the package from their fulfillment center to the customer’s door, including printing the shipping label. The cost of shipping varies based on zones, shipping speed, dimensional weight, carrier, etc.

Is a 3PL Right for You?

A 3PL could be the answer for your ecommerce business if:

- You ship 100+ orders a month

- Your garage or spare room is no longer enough to store your inventory

- You want to compete with companies that offer 2-day shipping so you can meet (and exceed) customer expectations.

- You want more control over the total customer experience.

- You need help managing your supply chain.

Order Volume

There’s no magic order volume right for every business. For some, it may be more, but for others it may be less. The real deciding factor is an increase in order volume that you cannot keep up with. If you’re asking friends and family to help you, it’s time to outsource fulfillment to the experts.

Why? You’re spending time on low-value activities (picking, packing, shipping) when you could invest that time in value-added activities (onboarding new customers, marketing, etc.)

Inventory Storage Space

Whether it’s a garage, your dining room, or spare bedroom, if you’re finding that you no longer have the room to store all the inventory you need to pack and ship your orders, it’s time to reclaim the space and work with a 3PL.

Fast Shipping

Thanks to Amazon Prime and its 2-day shipping, that’s become the new standard for ecommerce. If you’re fulfilling orders yourself, that offering can really do a number on your profit margins. Leveraging a 3PL also means you’ll get their volume discounts and be able to ship from multiple zones, which makes it easier to get products to everyone within two days, no matter where they are in the U.S.

Considerations When Choosing a 3PL Provider

At this point, you’re convinced you need to find a 3PL provider – but now, you don’t know how to choose the right one for your business needs.

Here are some topics to consider as you decide whether a logistics provider is the right solution for your business:

- Purpose and scope

- Details on logistics operation

- Impact on CS

- Area of service

- Operational challenges

- Changes to current procedures

- Impact of the transition period

- Discuss past experiences and difficulties

- Financial and time costs

- Overall price

- Setup time

- Continued responsibilities

- Requirements and processes

- New procedure requirements

- New technology requirements

- Overall Compatibility

- Benefits and advantages

- Faster fulfillment

- Lower carbon footprint

- Greatly reduced risk and investment

- Bulk labor and shipping discounts

- Value-added services

Here are some critical areas to evaluate as you meet with potential providers and negotiate a contract, focusing on their core competencies and expertise in EDI.

- Flexibility

- Scalability

- Locked in pricing

- Annual negotiations

- Business experience

- Years in business

- Management experience

- Quality of workforce

- Business trends

- Growth strategy

- Leading accounts

- Lost accounts

- Support & Security

- Data privacy

- HR and CS

- Sufficient business insurance

- Financial arrangements

- Transparency

- Recapture of excess profit

- Performance incentives

Consider these talking points when comparing providers and negotiating the terms of your contract. Some aspects may be more important to you than others, but it is important to have a complete understanding of how a company operates before partnering with them to represent your business.